UTM Waterjet Cutting

We have been using CNC waterjet cutting machines to cut materials ranging from stainless steel to carbon fiber parts for decades. It’s proven to be a great option for many customers looking for precision waterjet cutting of metal and non-metal materials quickly, often shipping products the same day, and with no tooling charges. We can handle materials up to seven inches thick, twelve feet long, and six feet wide, and cut them accurately to within +/- .005 inches if necessary.

Our waterjet cutting service has been used to cut prototypes for jet engines, radar systems, automotive parts, by artists to create unique pieces of artwork, to cut marble, to create beautiful and artistic stone inlays, and much more. Our CNC waterjet cutting machines will cut any metal, plastic, rubber, fiber (including carbon fiber), stone, or wood in either small prototype runs or large production runs. All of this with no tooling charge. Just send us your DXF/DWG files and leave the rest to us.

Advantages of Waterjet Cutting

With waterjet cutting service you can cut almost any type of material. Precision waterjet cutting is especially ideal for cutting materials that cannot be cut by a laser or thermal cut. Materials like titanium, granite, aluminum, marble, stainless steel, carbon steel, Inconel, concrete, stone, glass, plastic, rubber, foam, tile and ceramics.

With waterjet cutting service, you can reduce costs and speed up processing by eliminating or reducing expensive secondary processes. Since no heat is applied to the material, cut edges are clean with minimal burr.

Problems such as thermal cracked edge defects, crystallization, hardening, and reduced machine- or weld-abilities are eliminated. Parts remain flat and there is no tooling to design, build, test, maintain, or modify.

CNC waterjet cutting machines have nesting capabilities ideal for prototypes with maximized material yield. A CNC waterjet cutting machine maintains accuracy after numerous runs where some other tools may dull or need to have tolerances rechecked.

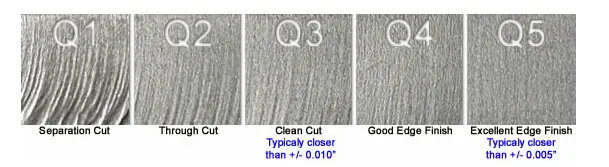

A CNC waterjet cutting machine can cut materials with a variety of speeds achieving either a great deal of accuracy with very smooth edges or a lower level of accuracy with rougher edges. If the tolerances required for your application are low, cutting speeds may be greatly increased to save money. The numbered images above, from a very informative article on “waterjet cutter” on wikipedia.org, clearly illustrates the variation in cut quality.

Benefits of Waterjet Machine Manufacturing

- Minimal heat affected zone

- Up to 6′ X 12′ and 7″ thick

- No heat distortion

- Cut edges are clean with minimal burr

- The positioning accuracy is +/-.005

- Kerf width: .040″

Other Advantages of UTM’s Waterjet Machine Manufacturing

- Prototypes & development runs

- Short or long run production without tooling cost

- Complex shapes or difficult materials

- CAD design & engineering services

- Fast turnaround

Industries Served

United Tool & Machine Corp.’s waterjet cutting service supports a wide range of industries, delivering accuracy and efficiency for projects of all sizes:

- Aerospace & Defense – Jet engine components, radar system parts, and other high-precision hardware.

- Automotive – Prototypes, specialty parts, and components requiring smooth finishes and exact tolerances.

- Architectural & Artistic – Intricate patterns cut into stone, metal, and composite materials for decorative or structural use.

- Electronics & Manufacturing – Precision waterjet cutting for clean edges and repeatable results in both small and large production runs.

- Custom Fabrication – Projects needing specialized shapes or materials cut with accuracy using our CNC waterjet cutting machine.

Ready for Sharp Results? Request Your Quote Today

We welcome projects that demand accuracy, clean cuts, and reliable delivery. If you have CAD files ready, send them to our team for a prompt review and cost estimate. Our staff is ready to answer questions about materials, tolerances, and scheduling. Contact us today to learn how our precision waterjet cutting capabilities can support your next project.